AGV-Automated Guided Vehicles

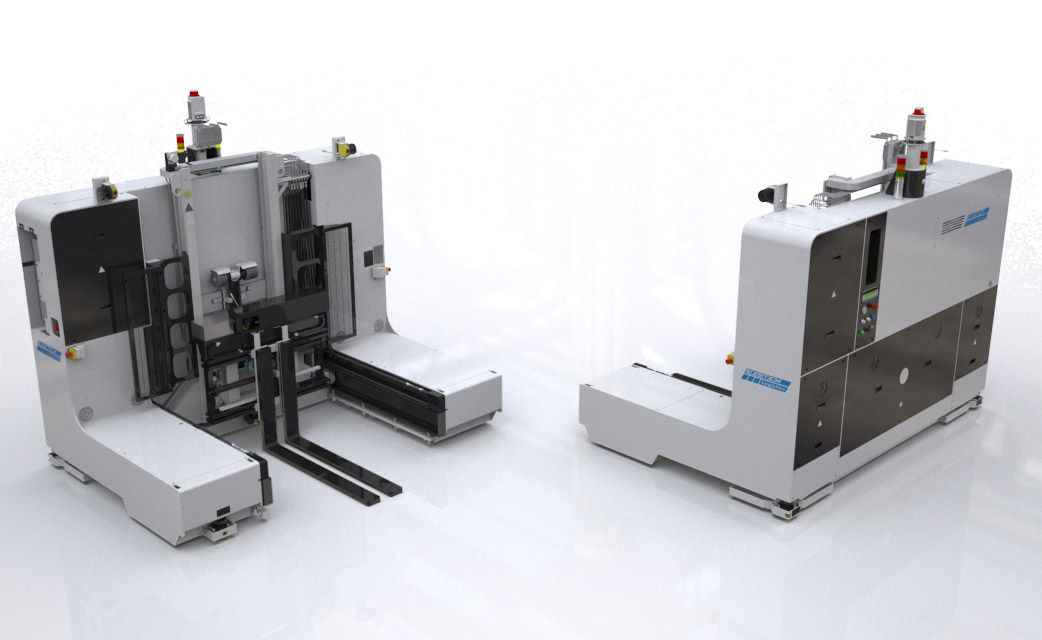

COUNTERBALANCED FORK VEHICLES

Ideal for floor-to-floor handling of pallets, reels and containers of various types, they easily interface with shelves, production lines and conveyors.

VERSIONS

Counterweighted vehicles can be customised according to the capacity and height they need to reach. These vehicles can be customised and equipped with a range of options: additional safety sensors, specific handling devices based on customer needs.

APPLICATIONS

- Production line infeed

- End-of-production line handling

- Floor operation

- Block storage

- Load-on-load

- Racks (single position rack, drive-in rack, gravity rack, mobile rack, mole rack)

ADVANTAGES

- Manoeuvering in restricted spaces

- High-level storage

- Handling of different Loading Units with the same vehicle

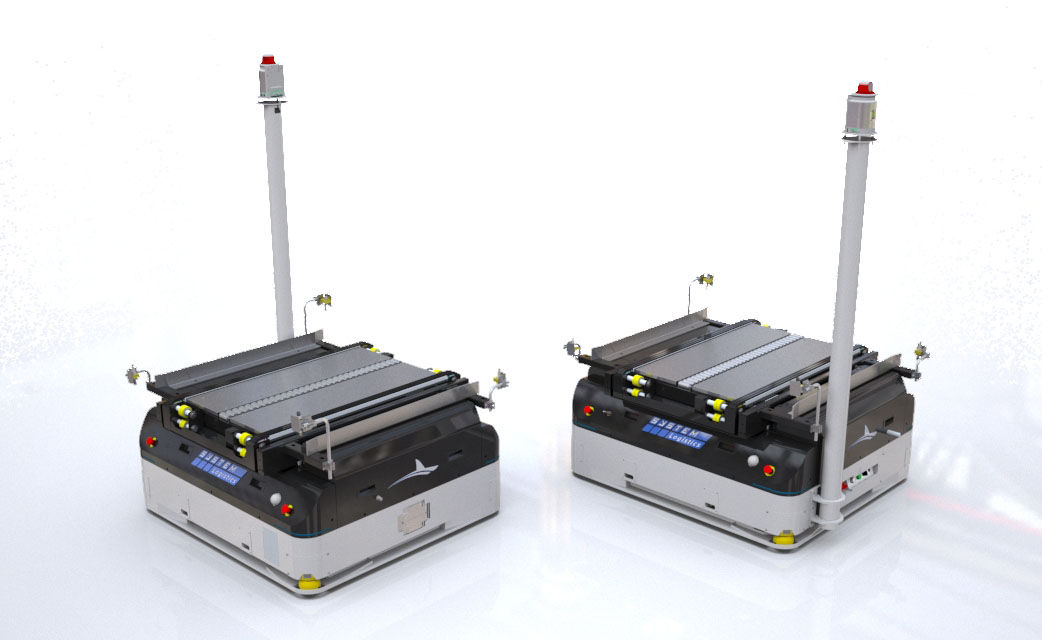

shark

Shark is the most compact and versatile product in our range. It is capable of moving in all directions and working in narrow spaces. Its dimensions are actually similar to those of the load carried.

MAIN APPLICATIONS

Shark is mainly used to connect the production lines with the automatic warehouse. It can also be used to handle products between the various internal conveyor systems, to serve the robotised stations as well as the automatic picking bays.

ADVANTAGES

The ability to handle loads without using fixed mechanical structures makes Shark extremely flexible and modular.

VERSIONS

This vehicle may come equipped with roller tables, chains or lifting devices of various type, depending on the intended application.

CONVEYOR DECK VEHICLES

- Vehicles with on-board conveyors

- Driving/steering front wheel and two idle rear wheels.

- Transport with chains, Roller tables and Belts

- Width: 1,500 mm

- LUs carried: 2

- Load capacity: 3,000 kg

- Elevation: min. 750 mm

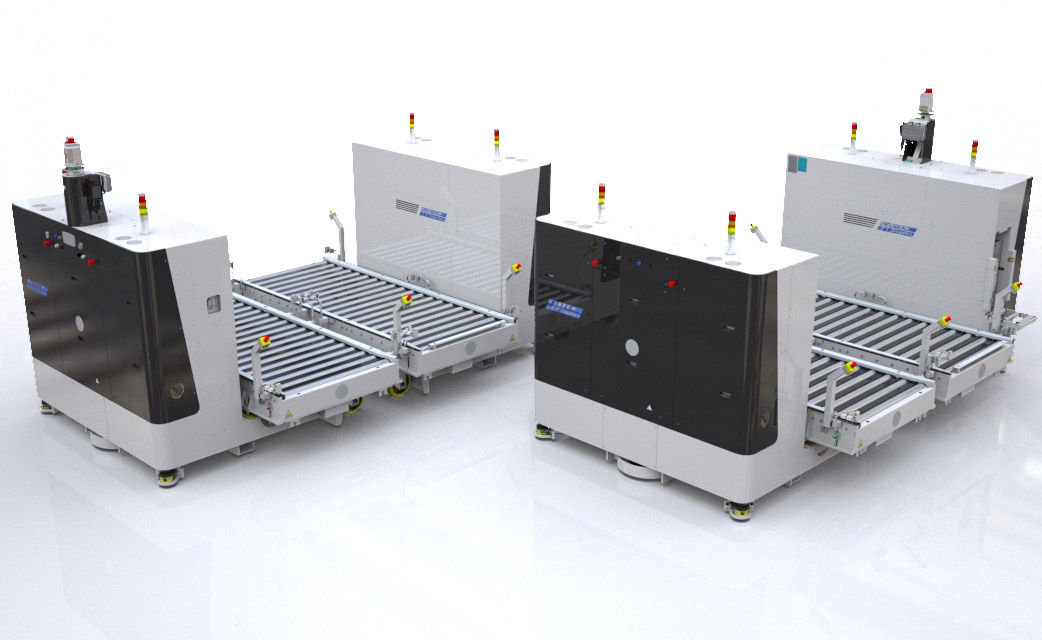

FORK QUAD VEHICLES

These vehicles are suitable for handling several loading units among operational positions at different heights, thanks to the forks they are equipped with.

MAIN APPLICATIONS

These vehicles are the ideal solution to handle the loading units from the finished product outfeed to the storage areas, be they on the ground, at different heights or within other industrial automations. In addition, they can be used to handle loading units among the different automations in the system, as well as the material infeed stations towards the production lines at different operational heights.

ADVANTAGES

As opposed to the Quads, the loading units are picked and stored by means of forks, and can therefore operate at different heights. They can carry several loading units at the same time, without needing to modify the existing mechanical structures.

VERSIONS

Our range of forked quad vehicles varies in terms of number of loading units handled.

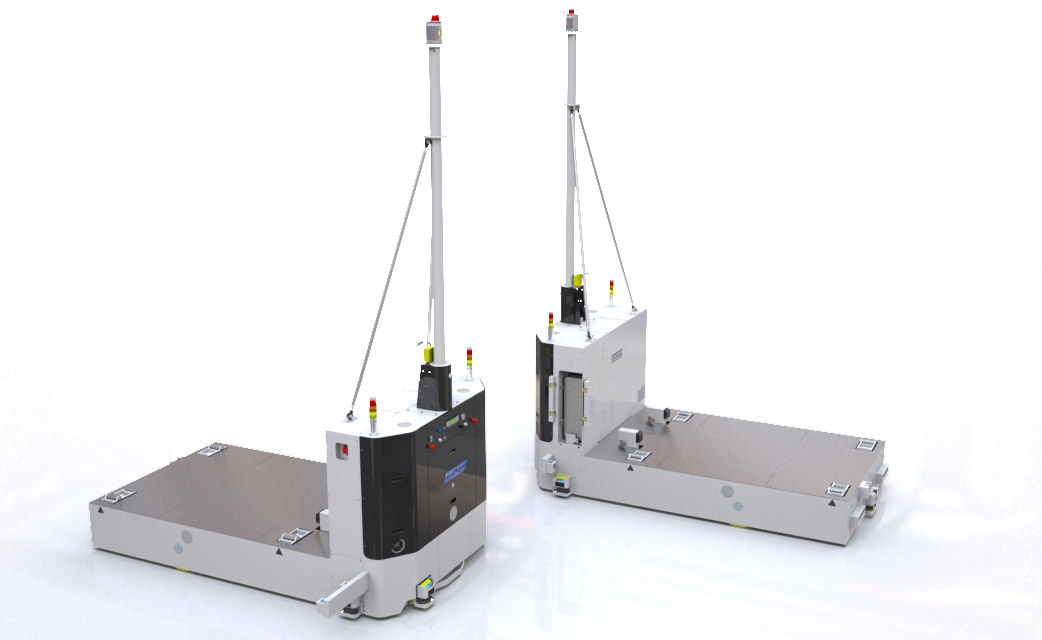

OUTRIGGER VEHICLES

This type of automatic vehicle is the ideal solution to handle loading units of various dimensions, weight and type. The idle wheels are positioned next to the pallet barycentre, thus assuring high capacities and manoeuvrability in narrow spaces.

MANY APPLICATIONS

These vehicles are particularly suited for operations within production lines and conveyor systems of different kinds, to connect different types of automation systems and storage of heavy loading units.

ADVANTAGES

Because of their high stability, they require shorter manoeuvring spaces and are also suited to low capacity floors.

VERSIONS

System Logistics manufactures different AGV Outrigger versions that differ in capacity and height. Also these vehicles can come equipped with different accessories, based on the design specifications.

CUSTOMISED VEHICLES

- Lift deck vehicles

- Bilateral

- Inox

- Heavy duty

- Stainless steel vehicles

- Driving/steering front wheel and two idle rear wheels.

- Grade 316 stainless steel vehicles resistant to saline environments for processing meat and dairy products.

- The vehicles are manufactured with IP65 protection rating for withstanding sanitization processes using water jets and detergents.